turbine flow meter working principle ppt

A turbine-shaped inlet section forces the axial flow entering the flow meter into a rotational movement. A simplified scheme of such flow meter consists of the 3 main parts.

Turbine Flow Meter Working Principle Instrumentationtools

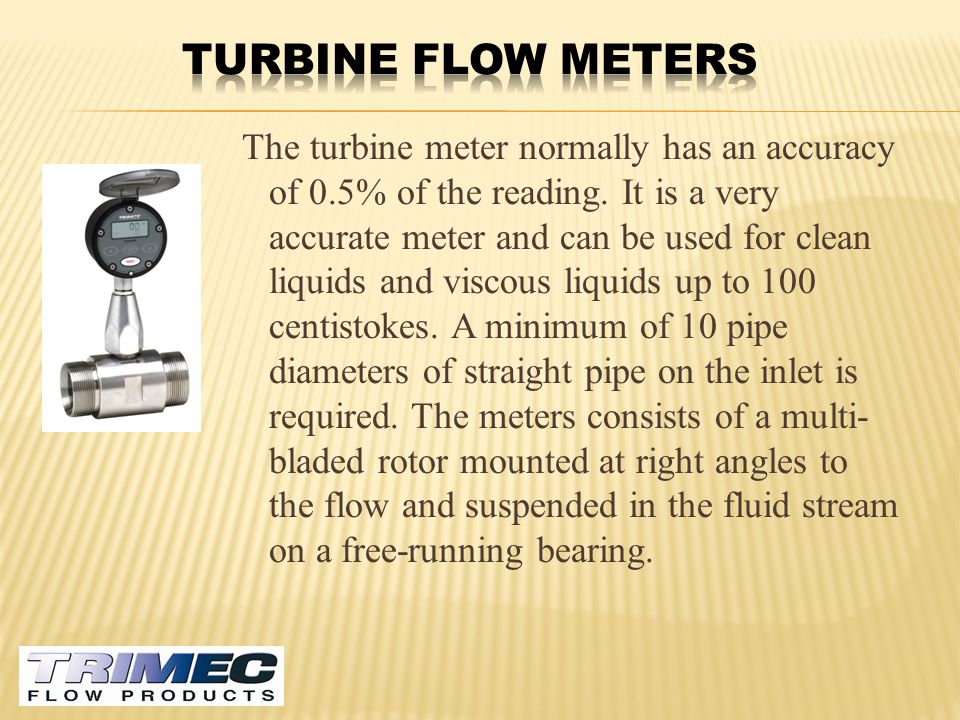

Better than 05 of reading Repeatability.

. A flow meter is a device that measures the flow rate of a fluid. Kaplan Turbine The Kaplan turbine is a water turbine which has adjustable blades and is used for low heads and high discharges. Accurate flow measurements of gases and liquids are required for the better control and quality of.

Length of the rectangular box is 12 inches. There are many types of flow meters available for use in industrial automation. DP Cell Ultrasonic Flow Measurement Devices Examples.

Such impeller is multi-bladed wheel. The voltage induced across a conductor as it moves at right angles through the magnetic field is proportional to the velocity of that conductor 6. It consists of a flow tube with end connections and a magnetic multi bladed free spinning rotor impeller mounted inside.

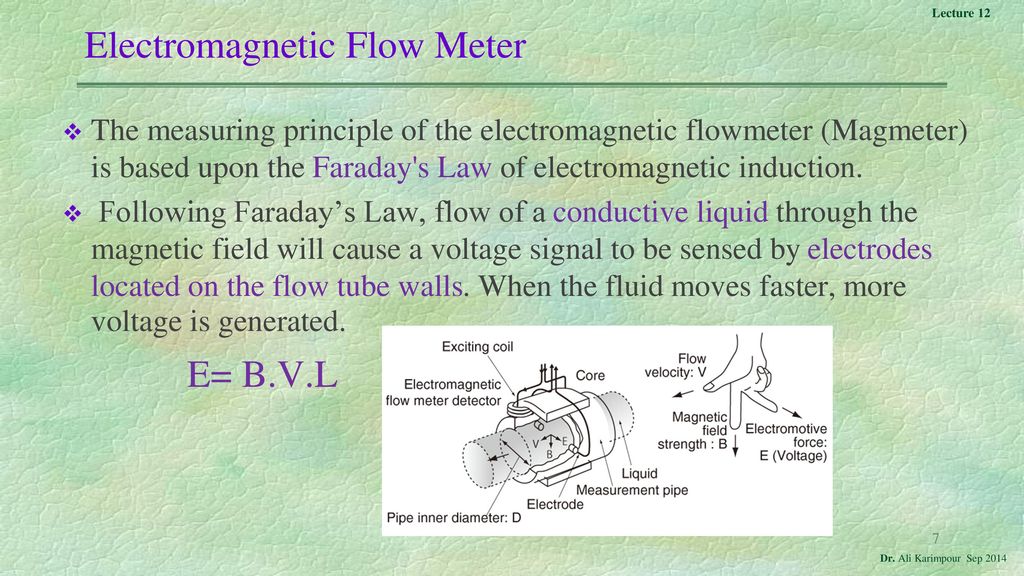

These meters are an ideal solution when high accuracy compact size and fast response are critical requirements. If this goal is achieved the turbine blades will achieve a rotating tip velocity directly proportional to the linear velocity of the fluid whether that fluid is a gas or a liquid. Principle of Magnetic Flow Meter Based on Faradays Law Magnetic flow meters works based on Faradays Law of Electromagnetic Induction.

The objective of our presentation is comparisons of different flow measuring devices. -01 of reading Pressure drop. As the blades on the rotor pass through the magnetic field of the pickup an electronic pulse is generated.

DE-58 Sector 3 Industrial Area Bawana. Depending on the product to be measured whether it be liquid or gas some basic principles apply to how the meters work. 05 bar at maximum flow Working pressure.

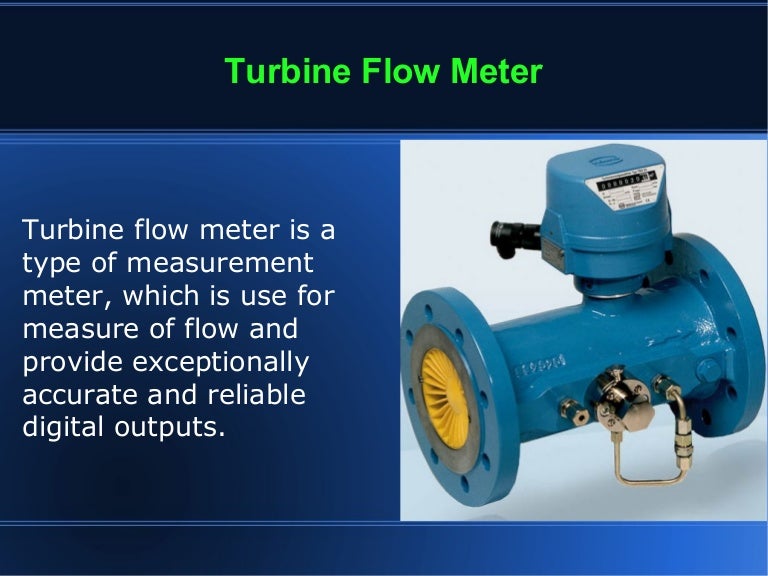

Isolate the instrument Drain Verify correct replacement part Install Verify pressure tight Un-isolate slowly to prevent slamming the float In service leak check Flow Instruments. Abstraction of heat from a heated body by an enveloping gas flow Hot-film Anemometer T between Rh and RT constant The loss of heat depends on the number of molecules that collide with Rh. Turbine flow meter is a device for measuring the volumetric flow rate of gases or liquids passing through a pipeline per unit of time.

When flow exists there is a constant differential pressure across the float Replacing a Rotameter. Working Principle The operation of a Electromagnetic flow meter or magmeter is based upon Faradays Law which states that. The generation of vortices is known as Karmans Vortices and culmination point of vortices will be approx.

As fluid flows through the turbine meter it impinges upon turbine blades that are free to rotate about an axis along the center line of the turbine housing. A reducer is used at the incoming side of the meter. The rotor shaft spins on bearings.

Flow meters are flow measuring instruments used to measure the linear nonlinear mass or volumetric flow rate of a gas or a liquid. A fluid flowing with a certain velocity and passing a fixed obstruction generates vortices. The fundamental design goal of a turbine flow meter is to make the turbine element as free-spinning as possible so no torque will be required to sustain the turbines rotation.

The speed or rotation of the rotor is directly proportional to the rate of flowing gas. Whereas the diameter and height of the turbine are 3 inches and 2 inch respectively. A Complete Flow solution Turbine Flow meter Application ZEST Specification Linearity.

The moving fluid causes the rotor to spin at a speed that is proportional to its flow rate. Turbine flow meter is used for translates the mechanical action of the turbine rotating in the liquid flow around an axis into a user-readable rate of flow. The angular velocity of the rotor results in the generation of an electrical signal AC sine wave type in.

When the fluid moves faster the rotor. Turbine flow meter is used for translates the mechanical action of the turbine rotating in the liquid flow around an axis into a user readable rate of flow. In line with the flow.

In the case of the turbine meter the flowing gas velocity is represented by the rotation of the rotor itself. Fluid entering the flow meter is first conditioned by the inlet flow straightener which reduces turbulence in the fluid. Orifice meter Venturi meter Rota meter Pitot tube.

Of the Turbine Flow Meter The Turbine flow meter axial turbine was invented by Reinhard Woltman and is an accurate and reliable flow meter for liquids and gases. Blades on the rotor are angled to transform energy from the flow stream into rotational energy. The most diverse substances are transported and distributed in piping system in every single day they may include solvents chemicals oilgas drinking water.

Working Princple of Turbine Flow Meter 4. A vortex core forms in the centre of the primary rotation. 101 to 1001 Response Time.

A turbine flow meter is used for volumetric total flow andor flow rate measurement and has a relatively simple working principle. Platinum thin-film resistor gas temperature Sensyflow FMT. Platinum thin-film resistor electrically heated RT.

The Kaplan turbine is an inward flow reaction turbine which means that the working fluid changes pressure as it moves through the turbine and gives up. The rotor is supported by a shaft that. The flowing fluid engages the rotor causing it to rotate at an angular velocity proportional to the fluid flow rate.

Liquid Turbine Flow Meters. Swirl Flow meters Principle. According to this principle when a conductive medium passes through a magnetic field B a voltage E is generated which is proportional to the velocity v of the medium the density of the magnetic field and the length of the conductor.

In this article you will get some basic idea of how a flow meter works. Flowing gas enters the inlet of the turbine meter and is immediately directed through a smaller channel created by. 100mSec Transmitter Enclosure.

A secondary rotation forms in the vortex core producing thread-like spirals. 12D downstream of bluff body. Turbine consists of a shaft which is fixed in the pipeline and an impeller.

Turbine Flow Meter is a volumetric measuring turbine type. What is a turbine flow meter how turbine flow meter work parts of a turbine flow meter advantages and disadvantages of turbine flow meter. 35 bar to 340 bar Turn down Ratio.

Flow meters are also known as Flow Gauges or flow measurement instruments.

Turbine Flow Meter Principle Advantages Disadvantages

Working Principle Of Turbine Flow Meter

Introduction To Flow Meters Ppt Video Online Download

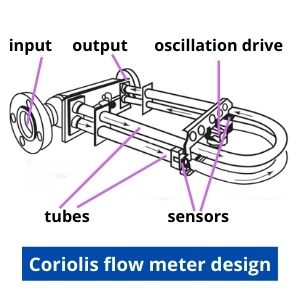

Coriolis Mass Flow Measuring Principle Bronkhorst

Turbine Flow Meter Explained Operation And Calibration Realpars

Working Principle Of Turbine Flow Meter

Module V Ppt Video Online Download

Coriolis Mass Flow Meter Working Principle Simple Theory Eltra Trade

Measuring Or Working Principle Of Turbine Flow Meter Youtube

Electromagnetic Flow Meters Working Principle Instrumentationtools

Swirl Flow Meters Working Principle Instrumentationtools

Working Principle Of Turbine Flow Meter

Electromagnetic Flow Meters Ppt Video Online Download

Ppt Introduction To Flow Meters Powerpoint Presentation Free Download Id 2327953

Measuring Or Working Principle Of Ultrasonic Flow Meter Youtube

Ppt Beneficial Flow Meters With Sincere Instruments Powerpoint Presentation Id 7968507

Module V Ppt Video Online Download

Lecture 3 Flow Level Temperature And Light Measurement Ppt Video Online Download

Ppt Turbine Flow Meter Powerpoint Presentation Free Download Id 2685380